Peeling machines and Peeling Lines

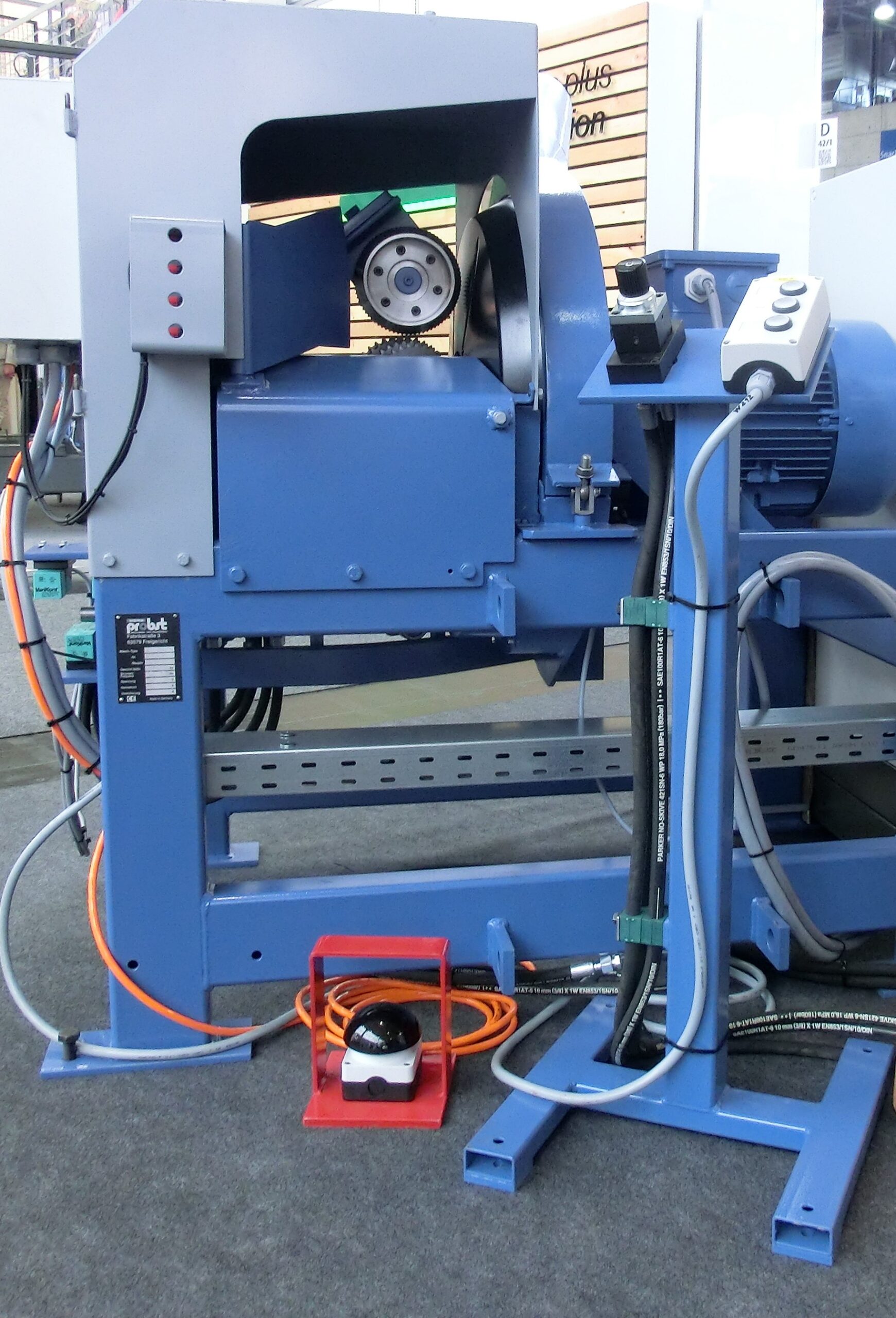

The high-speed peeler type WPSS 200 is a compact peeling machine for industrial use.

It is designed for peeling wood in the diameter range from 4 cm to 20 cm.

The machine is constructed for automatic operation, the wood infeed and outfeed can be effected manually or by transports.

It can be used as a single machine as well as in a complete production line for posts etc.

The machine is equipped with a curved peeling disc of 600 mm diameter. This enables an even processing of chestnut or acacia wood.

The cassette system permits to adjust the knives safely outside the machine by means of a gauge.

The hydraulic-electric remote adjustment is used to set diameter ranges for peeling inside the machine.

The upper rotating roller opens and closes hydraulically and is electrically controlled by photocell.

Upper and lower rotating rollers are hydraulically driven.

The drive for the peeling disc is a motor with reinforced bearings and special shaft.

The feed speed is infinitely variable from 5 to 14 m/min.

The machine is always supplied with hydraulic power unit and electric control cabinet as well as operating instructions, but without hydraulic oil.

Pole peeling machine type MSM 70

This machine is specially designed to produce telegraph poles. However, the end products are also used in timber construction (roof – and wall structures) or even in hydraulic engineering.

The diameter range of the trunks is from 8 cm to 40 cm.

The lengths from 4.0 m to 14.0 m (16.0 m) can be processed.

The two peeling arms (for pre-peeling and final peeling) ensure a smooth surface that complies with European standards.

Flat, easily to resharpen knives are used.

The knives can be changed in just a few minutes.

The peeling process is automatic. The wood can be supplied by manually moved transport cars (without electric drive).

The log is rotated with two hydraulically driven rotating rollers.

Of course, it is also possible to supply an automated pole peeling line equipped with a multi-strand cross conveyor with inserter, with electrically adjustable infeed and outfeed cars (transporters) with pneumatic ejectors.

Contact us