Machines and Line for constructional timber

The round milled timber has a higher stability than square timber of the same dimension. This allows, for example, to build a free-standing hall up to 20 m in width from round logs (small wood) with a diameter of 14 cm.

For the production of round logs with profile for log houses, we offer both combined rod rounding machines Type RHM SR, i.e. round milling and profiling in one machine, and separate machines for round milling Type RHM and for profiling Type PM.

In practice, the wood is first cylindrical pre-milled, then air- or chamber-dried to approx. 12 % (fiber saturation point and less), afterwards, the timber is fed for milling to finished size and longitudinal profiling on one or both sides.

In the companies, that already have dried raw wood in sufficient quantity and/or process long wood up to approx. 10.0 m, a rod rounding machines with two cutter heads and with profiling units Type RHM B II-H is used.

It is also common practice to work with separate machines, i.e. first with a single-head or double-head machine and then with a separate profiling machine Type PM. This also depends on the in-house organization.

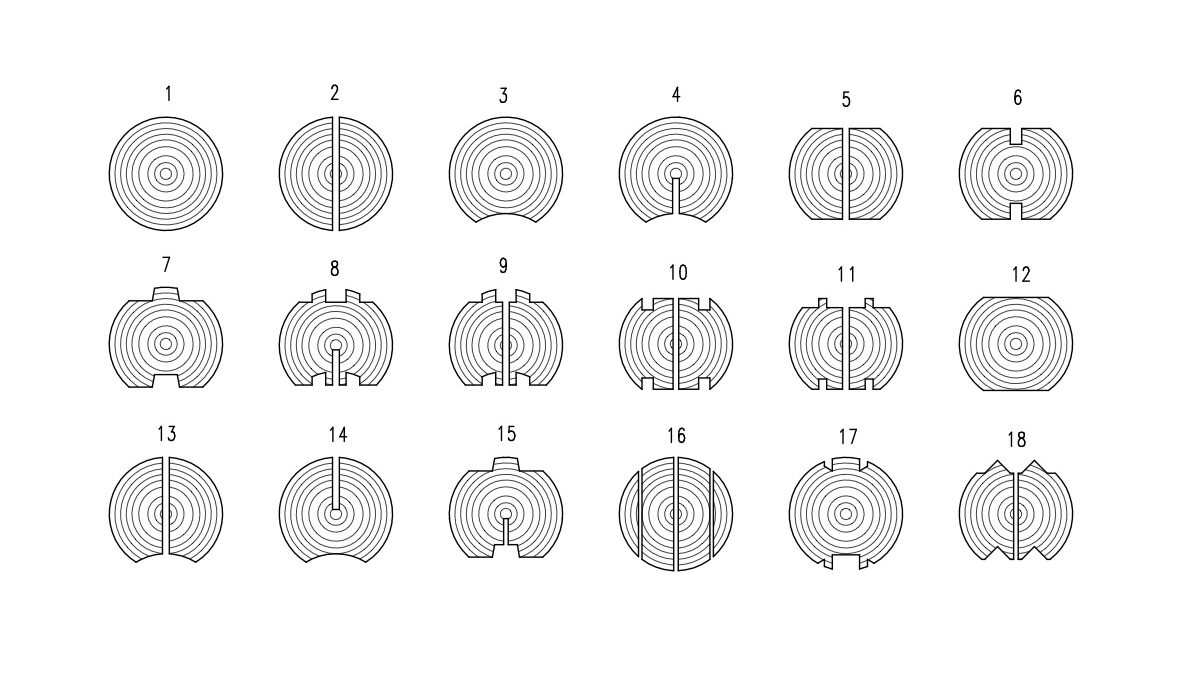

Determination of profiles and diameters is related to climatic conditions and requirements of the customer.

Our machines are used in cold regions such as Canada and Russia, as well as in hot and humid regions such as Thailand.

We also produce machines in manually operated version such as a cross drilling machine Type QBV 200, which allows many individual possibilities for the wood with diameter up to max. 20 cm.

Also, machines for corner joints for diameters up to 30 cm as well as slot milling machines for window and door installation are part of our machine program.

Contact us