Machines and equipment for further processing of round milled and peeled woods

WeMa Probst offers machines for pointing (pencil pointing or four-surface pointing), machines for making a cone or a chamfer, but also for splitting and cutting.

Depending on the production volume, you can use our machines with manual infeed and outfeed as single machines or in automated lines.

Machines type AKV with manual wood infeed

Depending on the design of the AKV, you can process the end of the round milled logs to

a cone up to diameter 7 cm,

a chamfer up to diameter 14 cm or 16 cm,

to reduce from 10 cm to 8 cm

or to make a pencil point for square logs up to 5 cm x 5 cm.

The machine is easy to operate and enables safe working thanks to a motor brake, a motor protection switch, a protective cover with a chip funnel, etc.

Depending on the version, the machine is also used, for example, in workshops for persons with disabilities

The splitting saw Type SPS is constructed to split round milled logs in the middle.

Its machining range is possible up to 14 cm or up to 16 cm.

The feed can be adjusted in steps.

The special advantage of the SPS is the height adjustment of the saw blade, so an optimal saw blade projection is achieved.

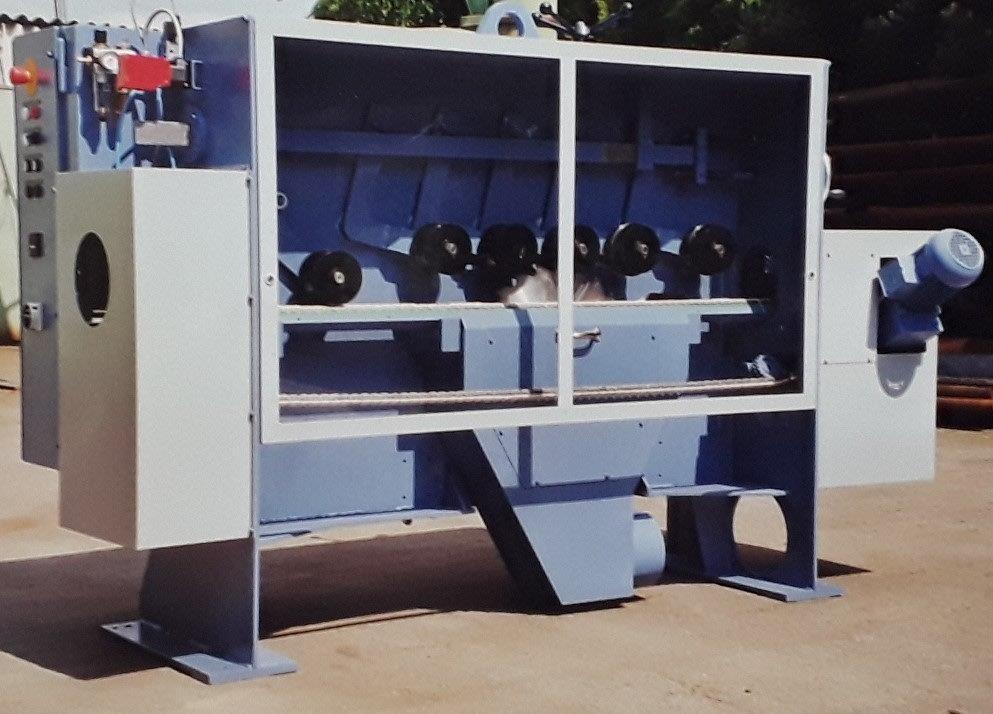

The pointing, chamfering and cross-cutting machine Type SFK is designed for processing of peeled and /or round-milled logs in automatic mode.

The SFK 160 /SFK 200 is constructed for machining diameter ranges up to 16 cm or up to 20 cm. In the standard version, it is equipped with a 70 cm diameter disc with 6 knives. In the Long Point version, a disc of 100 cm diameter with 10 knives is used.

It is not necessary to pre-sort the wood by diameter.

The possible log lengths from min. 1.5 m to 6.0 m (7.0 m) are individually adjustable.

During automatic operation, it is necessary that always the logs with the same length are fed to the machine.

Working operations of a SFK 160 /SFK 200:

– the wood to be processed is load onto the SFK from a conveyor.

– then, the logs are cut to exact length at both ends.

– when processing peeled logs, they are measured for diameter at both ends. This process facilitates later sorting of the finished product by diameter for transport in boxes (option).

– measuring on both ends defines the position of the pointed or the chamfered end (bigger or smaller end, pointed or chamfered).

– it is pointed or chamfered on the defined side.

– subsequently, there is the option of individually marking the wood on one side with a branding stamp.

Contact us