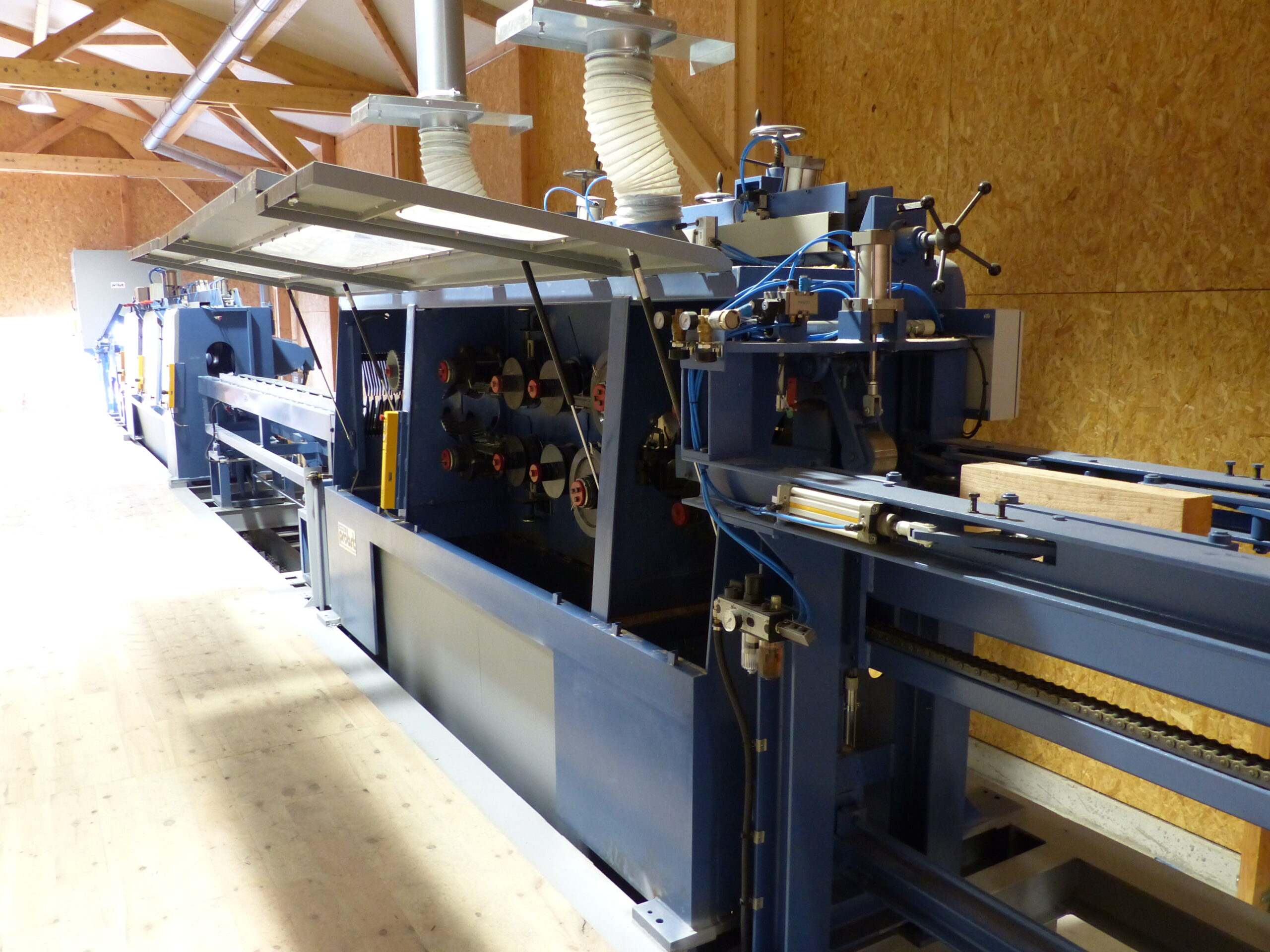

Profiling Line (sawmill line for small timber processing)

The profiling line is constructed for timber in diameters on top from 10 up to 25 cm and in lengths from 1,0 m. Depending on dimensions, log form and profile, cutting capacities of approx. 50 m³ up to 120 m³ of finished product per 8 hours/shift can be produced.

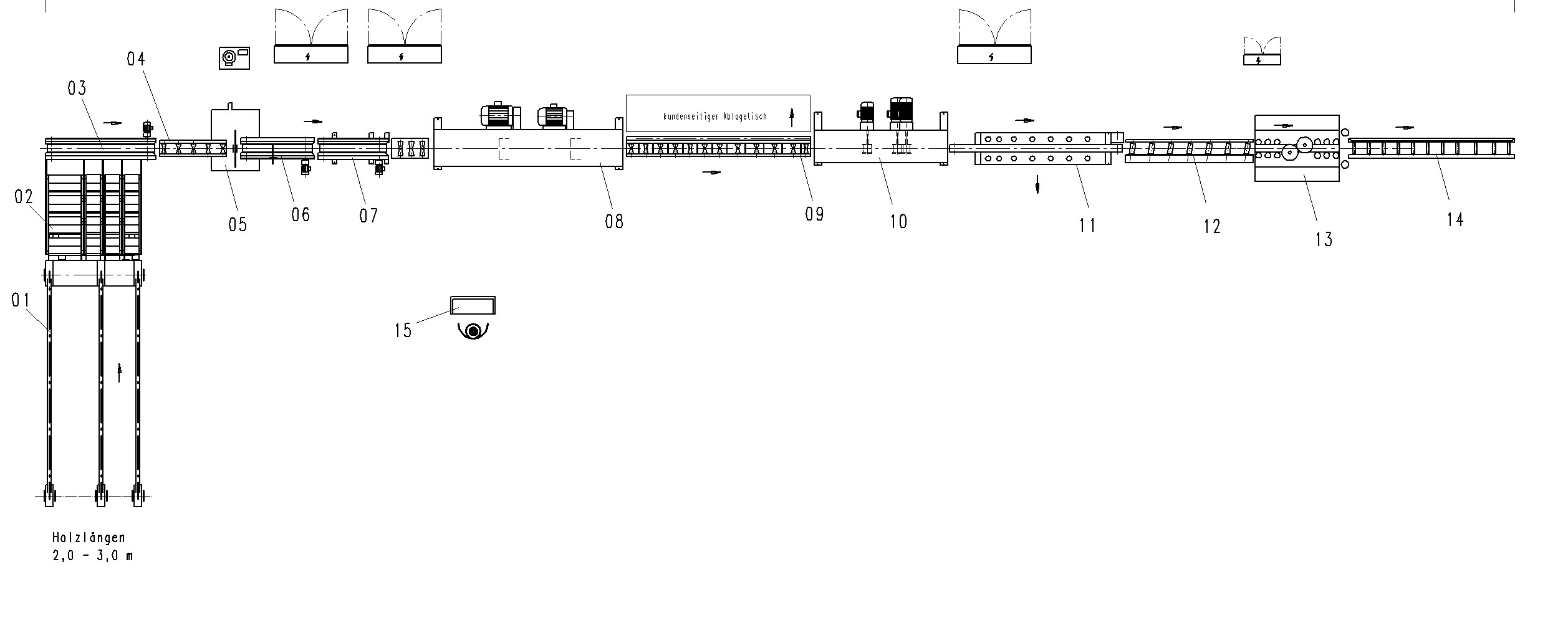

1

1 Dreisträngiger Querförderer

Stufenförderer

Einzugstrog

Kegelrollgang

Kappsäge

Einzugstrog und verstellbarer Anschlag

Einzugstrog höhenverstellbar

Rundfabfräsmaschine RHM 250

Kegelrollgang

Profilier und Mehrfachsägemaschine PSM250

Transportkette mit seitlichem Abwurf

Rollgang mit schräg angeordneten Rollen

Doppelwellen Vielblattkreissäge

Rollgang nicht angebtrieben

Bedienpult

The Line is charged with the logs pre-sorted by diameter. If the trunk is not straight (curved), it is cut in the middle by cross-cutting saw (KSA).

Because the shorter the wood, the straighter it is, the higher the wood output.

The timber is fed by centering transports into a rod rounding machine with 2 adjustable cutter heads (RHM II-H), which permits to process the timbers from start to finish at a feed rate of 6 to 34 m/min.

Depending on the diameter, the feed can be reduced or increased by an electronic feed control.

The middle of the trunk is the reference point for processing in the entire Line.

The Rounder permits to optimize the timber nature: root runs, knots; oval shape and conicity are eliminated, thereby permitting continuous further processing of the woods.

After the RHM, the round milled timber is transported to a profiling and sawing machine (PSM) with 4 profiling shafts.

Depending on the setting of the profiling tools, two or four fully prismatic sharp-edged side boards and the main model with different width steps can be cut.

After the PSM, the side boards are separated from the model by a special transport.

The model is conveyed into a horizontally operating cutting saw and is sawn to boards in various fixed cutting dimensions.

It is useful to produce the same profile over one whole shift to reduce set-up times.

The profiling Line offers many advantages that ensure considerable economic efficiency and

- high timber output,

- low space requirement,

- low staff costs,

- low energy costs,

- Separate chip types such as sawdust and chips

- Separate storage of side boards, top and bottom boards as well as the main board.

The sawn material can be used to produce pallets, parquet, elements for glued beams etc.

The design of the Lines is made individually according to the wishes and requirements of the customer.

Contact us